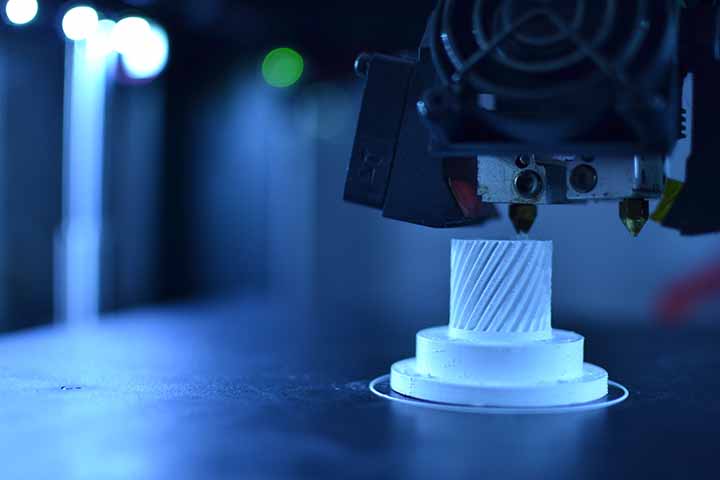

Nanoe’s Zetamix product line makes our powders and their properties available to most 3D FDM printers. Inspired by ceramic powder injection processes, the Zetamix manufacturing process consists of three stages: printing, debinding and sintering. With a density of over 99%, the finished product enjoys the same properties as its counterparts made with traditional methods.

This technology was developed through the EU’s Horizon 2020 research and innovation program.

This technology was developed through the EU’s Horizon 2020 research and innovation program.

Before starting the shaping of the part process, our filaments are composed of polymer binders and 50 to 60% ceramic powder. We offer three ceramic filaments: White Zirconia, Black Zirconia and Alumina.

We have also developed a stainless steel filament (316L) and are currently working on the development of silicon carbide, silicon nitride, tungsten/cobalt carbide and titanium filaments.

Our technology is accessible to all and is aimed at industries and research laboratories as well as artists and designers. Nanoe offers not only filaments but also a package consisting of a 3D printer, a debinding kit and an oven.

The three stages of the process have been designed for being easy and fast to grasp which in turn induces low investment costs due to the time gain. Since our filaments are compatible with most FDM machines on the market, our technology works as an open system. Debinding and sintering can be carried out with your own equipment as well as with the one proposed by Nanoe.

Finally, a training course is offered with the Zetamix pack during which a 3D expert accompanies you for the printing and finalization of your first parts.

The Zetamix system is ideal for prototyping and customising of parts. It allows you to create ceramic or metal parts quickly and cheaply. This technology is recommended for in-house tooling and makes it possible to respond easily and quickly to various production problems.