High wear resistance | Impact resistant | Recommended for wear parts

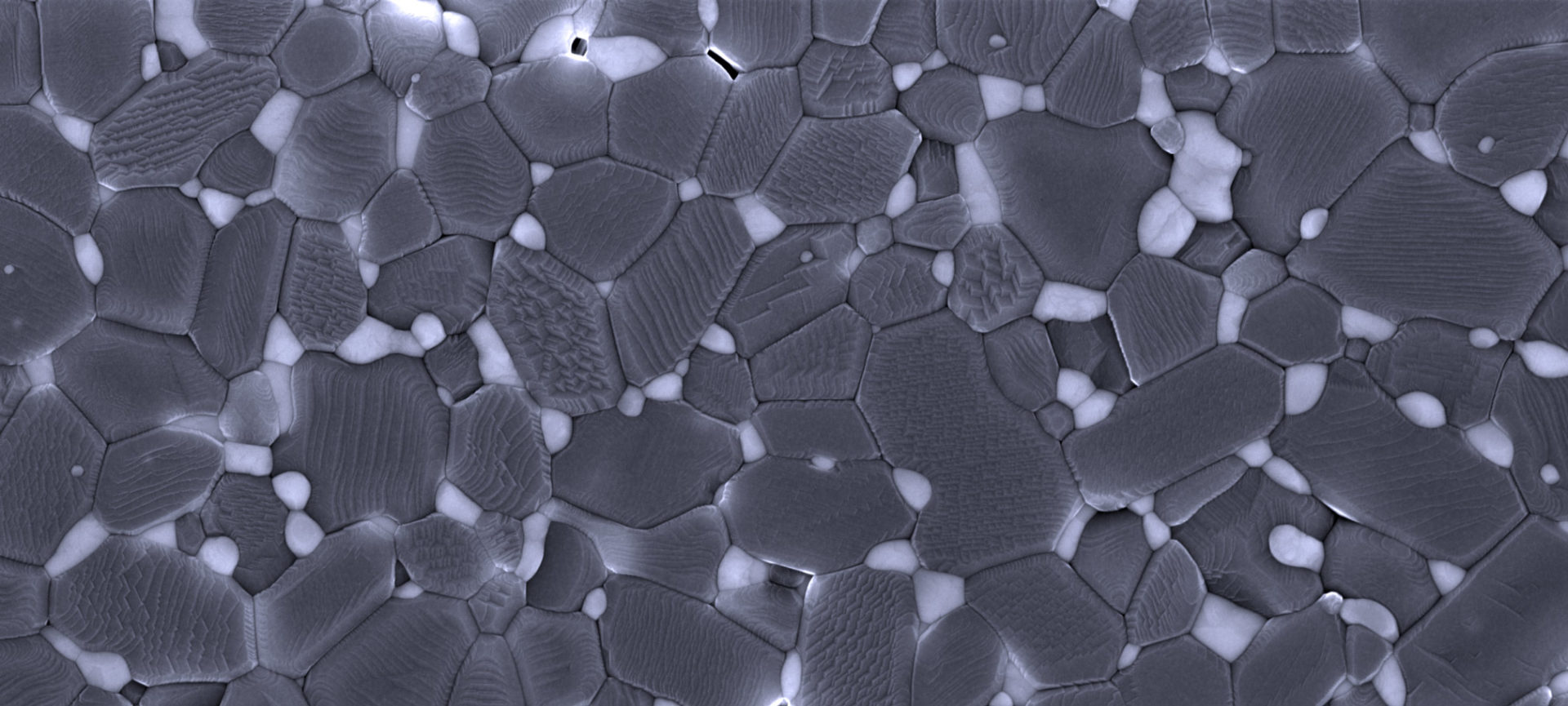

ZTA (Zirconia Toughened Alumina) is an alumina and zirconia composite material mix : this helps to get the properties from both material in a single ceramic powder. The ZTA then inherits of high temperature and wear resistance from the alumina but also the impact resistance from zirconia. The different alumina-zirconia ratios offered by Nanoe enables the client to pick a product best suited to his needs. Thanks to our unique know-how on powder synthesis, the parts made with our ZTA have a very fine microstructure with a high homogeneity, resulting in higher mechanical properties.

ZTA12 is a 88% Alumina and 12% Yttriated zirconia mix. This composition, the result of extensive research carried out by our R&D department, ensures an optimal level of hardness, electrical resistivity and hydrothermal ageing resistance. Like for the ZTA25 powder, our ZTA12 powder has a high wear resistance, we can also offer chrome-doped ZTA12 to have an even better wear resistance.

In order to best meet your needs, Nanoe delivers ZTA12 in the form that best fits your process. We are thus able to supply our materials in the form of ready-to-press granules, redispersible powders or feedstocks for ceramic injection.

Nanoe is able to adapt the ZTA to your request so that it meets your specific constraints, for example by adapting the alumina/zirconia ratio or by adding dopants.

Are you interested in Nanoe’s Alumina?