Using more efficient equipment to reduce the number of maintenance shutdowns and facilitate sterilization cycles is the challenge for all industries dealing with fluids in their manufacturing process.

Whether for the pharmaceutical, cosmetic or agri-food industries, ceramics are ideal for the production of pump bodies, valves, sensors or nozzles. Unalterable, they make it possible to manufacture durable, easily sterilizable objects that are resistant to the highest loads while eliminating the risk of pollution to the contents.

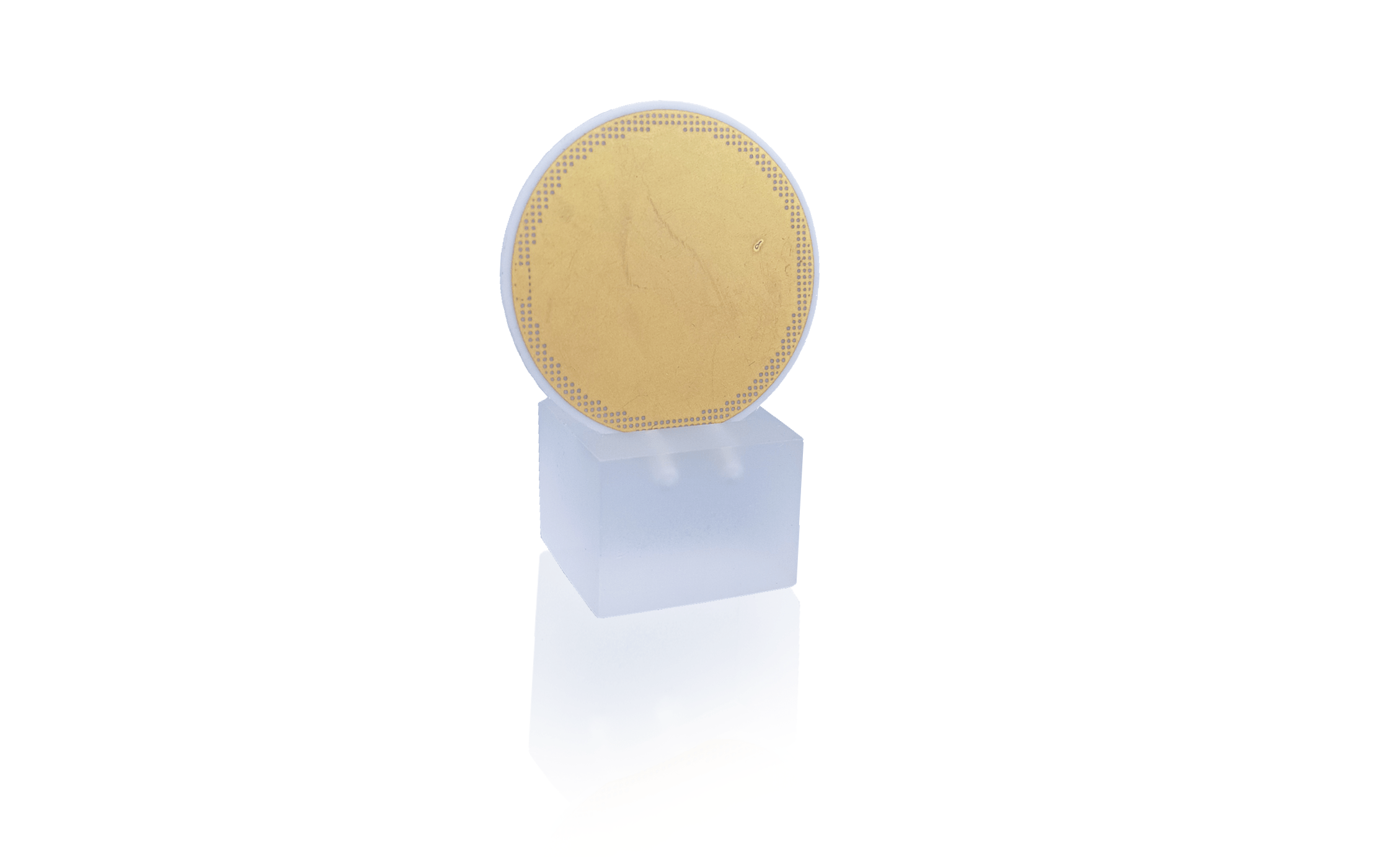

Pressure sensors for the chemical and agri-food industry must be as resistant as possible to chemical aggression. The Alumina proposed by Nanoe is recommended for this application because it has a density of 99% and is extremely pure. These qualities therefore allow better resistance to abrasion and corrosion, lengthening the time of use of the sensors.

Stainless steel is a widely used material for the production of filling and dosing pumps for many industries. However, this material is less resistant to corrosion and stress due to sterilization cycles than ceramic. The ZTA has good wear resistance, thermal shock and hydrothermal ageing and is a prime choice material for this kind of application.