Changing powders can require a bit of time to adapt in you production chain. Our engineer and sales team are at your disposal to implement rapidly our powder in your production chain all throughout your process whether it be for the choice of raw material or the usage of our powders on an industrial scale.

Nanoe’s sales team is composed of materials science engineers, we choose to do this because we feel that not only it is good to have a sales person but we find it is more interesting to have people who know about the materials to better understand and guide you for the buying process and not be shoving products down your throat. Our team will help you choose the ceramics best adapted to your projects, whether it be for the development of new products or for it’s improvement. You can fully trust our team as ceramics is our field, we know the properties and usage of these ceramics like the back of our hand. We will accompany you and advise you on the choice of powder who best fit the specifications you’re looking for.

In order to facilitate your industrialisation process our sales team will accompany you with the use of our powder with your production process as soon as the first tests phases. No matter what type of technology you’re using, whether it be pressing, casting, injection or even coating applications, are powders are compatible with each of these technology. So as to facilitate the use of our powder with each of these technologies, we provide our ceramic products under different formats: in granules ready to press, in feedstock for ceramic injection, redispersible powders or filaments for 3D printing.

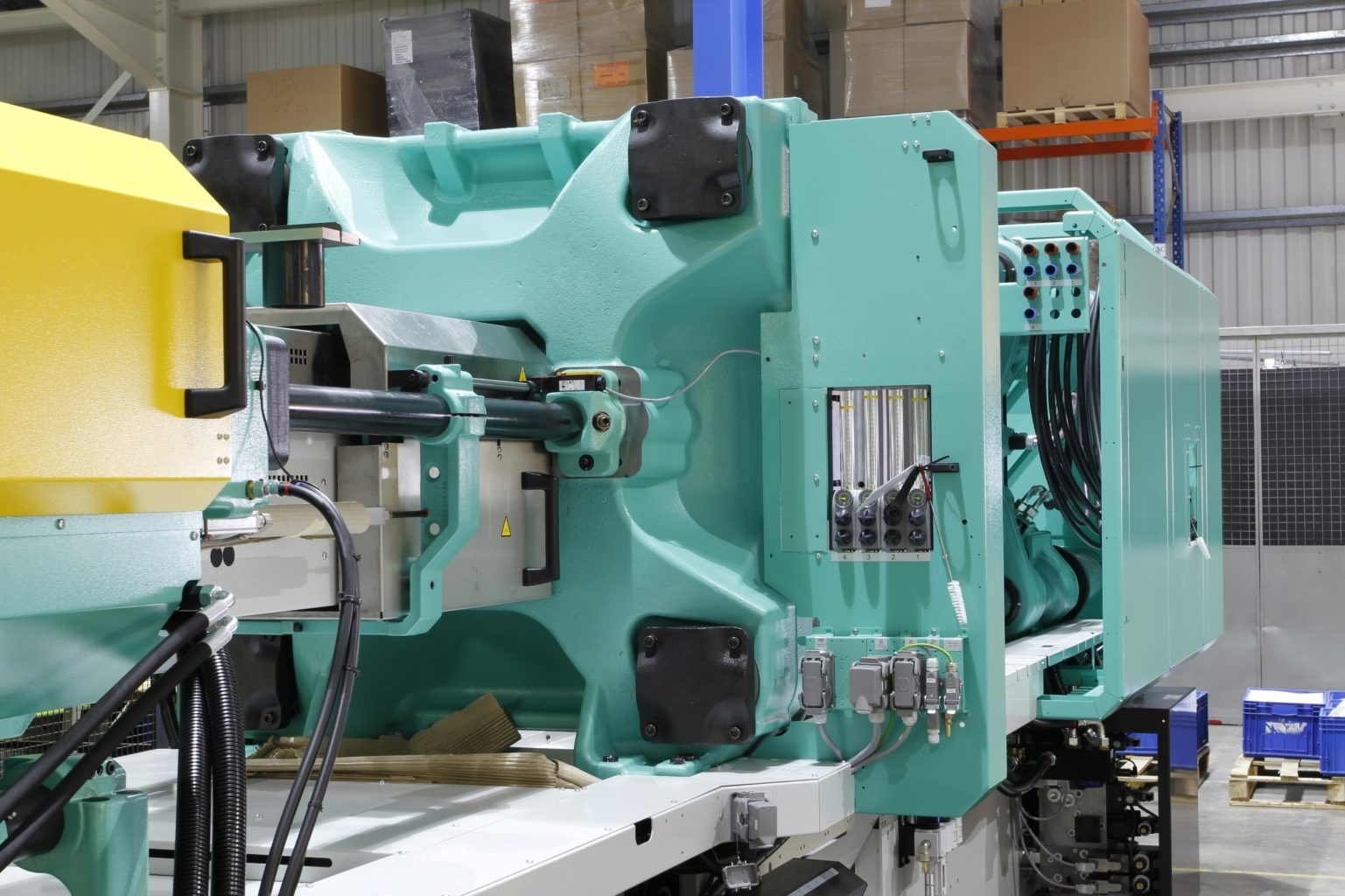

We will assist you for the first tries and also help you optimise the parameters for your pressing and injection molding machines as well as the parameters for the debinding and sintering.

We will carry out Failure Modes and Effects Analysis (FMEA) tests on finished products that you will produce with our powder to verify that it meets your specifications. For instance, we will examine the microstructure of the samples to evaluate the potential weak points in the part or in the shaping process. Thanks to this analysis, we are able to give you concrete solutions to better the existing system : machine or even sintering parameters.